FILSON LEGENDARY WAXED COTTONS

What worked then still works today. While science and chemistry have produced some amazing options for raingear in recent years, sometimes the best option for wet-weather protection has existed for over a century. There are certainly situations when technical waterproof fabrics are a must, but there are also times when traditional waxed cotton is the preferred option. This article examines what waxed cotton is, how it came to be, and why we like it so much.

ANCIENT SOLUTIONS

Woven wool is made with tightly-spun yarns arranged on a loom and woven in a specific pattern, typically a twill weave with offset warp and weft yarns. Twill fabrics are characterized by diagonal rib that is created, and have a natural, supple drape. Compared to knits, woven wools tend to be more wind-resistant and less susceptible to snagging, since there are no loops used in the weaving of wool.

In ancient South America, latex from the rubber tree was used to make clothing waterproof. In 1823, Scottish chemist Charles Macintosh patented a fabric with rubber that had been dissolved in a naphtha solution sandwiched between two layers of fabric. These rubberized fabrics kept the rain out, though at the expense of any breathability. The rubber had problems with melting until the advent of a process called vulcanization was developed by Charles Goodyear in America and Thomas Hancock in England.

(1) Straw Raincoat - (2) Gut Parka

Evolution of Waxed Cotton

Historically, sailors have endured some of the wettest conditions imaginable, with no reprieve. In the fifteenth-century, mariners discovered that treating sails with oil made them more efficient, trapping more air while preventing water absorption. This prevented excess weight from slowing the ships. Sail fabric was treated with fish oils, tar, and eventually, linseed oil. For protection from rain and sea spray, they would fashion this oil-treated sailcloth (oilcloth) into capes and slickers, which became known as oilskins. But there were some downsides–the oiled fabric became brittle in cold temperatures and would discolor over time. Also, it didn’t last long and required frequent reproofing.

In the very early 1900s, a few U.K. companies, including Scotland’s Halley Stevensons and England’s British Millerain, began independently developing new fabric treatments using wax. Wax-treated fabrics were more weatherproof, stable, and longer-lasting than oilskins.

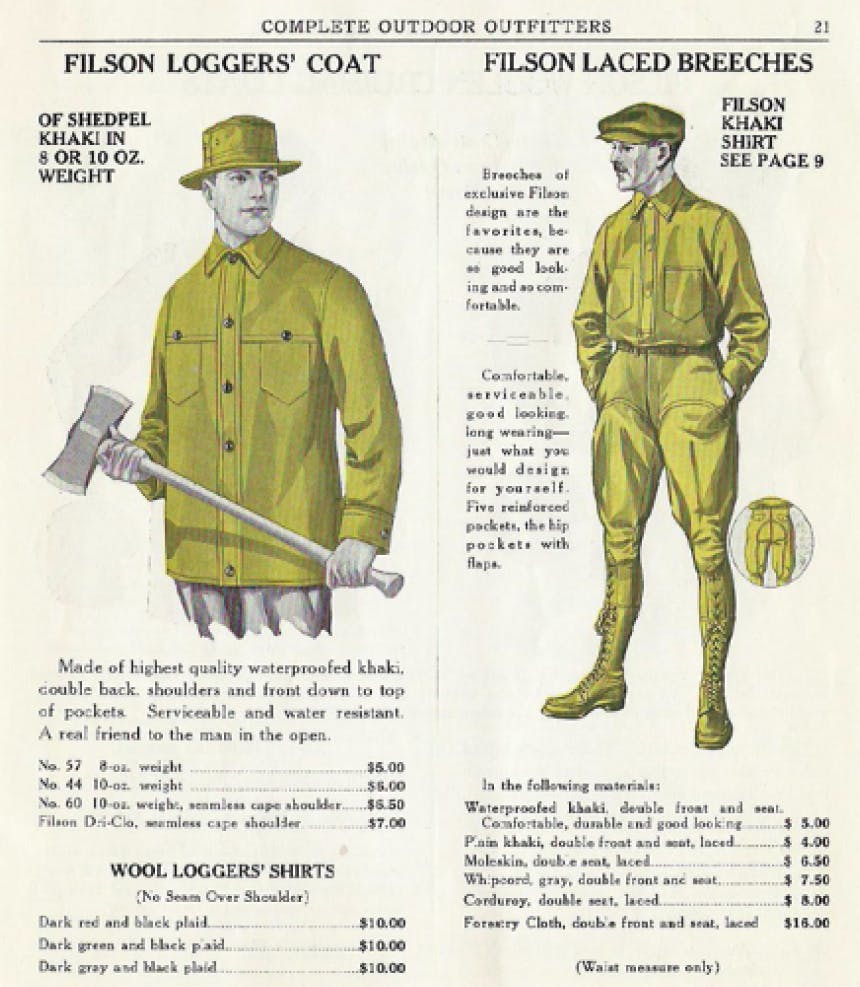

Clinton C. Filson was a pioneer in bringing to market tough, weatherproof waxed-cotton clothing. Our Original Hunting Coat, introduced in 1912, and our Double Logger and Cruiser Coats, as well as breeches, were all made with “waterproofed” cotton khaki:

(1) From our 1914 catalog - (2) From our 1922 catalog

While historical details are vague, it is believed that Filson obtained our earliest waxed cottons from traders who brought British Millerain’s paraffin-treated khaki drill fabric to North America. Because it was so durable, this tightly-woven cotton was issued to military troops around the world in the late 1890s. Treated with a paraffin wax, it was the precursor to Filson’s iconic oil finish Tin Cloth, and the tool of choice for keeping woodsmen, loggers and hunters dry in the rain-soaked forests of the Pacific Northwest. Filson’s time-proven waxed cotton clothing forged its reputation for toughness and weather resistance in extremely demanding, rugged conditions.

The Right Tool

There are many reasons to choose traditional waxed-cotton raingear when so many lightweight, technical options exist–let’s take a look at some.

Durability – tough waxed cotton such as oil finish Tin Cloth withstands tears and punctures far better than the lightweight raingear that goes on backpacking trips. While packable waterproof raingear is the tool of choice for many backcountry uses, bushwhacking through a thorny thicket would likely destroy it.

REASONS TO CHOOSE WAXED COTTON

Natural – wearing waxed cotton feels quite different than wearing nylon and polyester. There’s a quiet warmth to the fabric that many prefer. Cotton is renewable, and with smart farming practices, will be a sustainable source of clothing for future generations. It’s biodegradable and easy on our environment. The paraffin wax used to treat cotton is a nontoxic mineral-oil distillation, a byproduct of the petroleum industry. From candles and ski wax to cosmetics and crayons, the uses for paraffin in our society are numerous. No additional oil is extracted to make paraffin–as long as we use cars, jets and buses, paraffin will be produced as a clean byproduct.

Long-Term Value – Heavy-duty waxed cotton is a durable fabric that, with proper care, gets better with age. Just as a truck needs periodic oil changes, waxed cotton requires occasional rewaxing to maintain peak performance. After many miles and rewaxings, the fabric’s becomes polished into a smooth, leather-like surface that water just runs off. If holes or tears do develop in Filson waxed cotton products, we offer a repair service that greatly extends the product’s life. Investing in, and maintaining, top-quality waxed cotton can cost less in the long run, while minimizing landfill fodder.

Tradition – The idea of wearing the same jacket their grandfather wore while pursuing game appeals to many, much like the feeling of carrying a well-worn and cared-for vintage 20-gauge behind a hard-running Pointer. Others like to wear the same clothing that protected the lumbermen who opened up the Pacific Northwest. For some, a pleasant autumn ritual is to enjoy a bit of whiskey while rewaxing their chaps in anticipation of the pheasant opener.

These are but a few of the many reasons that, after a century of service, waxed cotton remains a viable solution for wet-weather protection. While it’s not the only tool in the outdoorsman’s kit, there are many times when it is absolutely the right one for the job.