When you’re outdoors and can’t escape wet weather, staying dry is a very real need. Quality rain gear not only keeps you more comfortable—in cold temperatures, it can prevent life-threatening hypothermia. Rain gear that strikes a balance between conflicting criteria such as water resistance vs. breathability, mobility vs. simplicity, and packability vs. durability solves problems for the outdoorsman. This article takes a look at some of the modern technologies available to keep us dry, and how they work.

HISTORICAL SOLUTIONS

Until fairly recently, the centuries-long evolution of raingear has revolved around treating fabric with oils, waxes, and rubber, each with their benefits and shortcomings. Technologies developed in the late 20th century have completely transformed how we think about and what we expect of rain gear.

In the 1960s, coated nylons entered the market—they were lightweight, waterproof, and inexpensive. But many were not durable and, like rubberized cotton, did not breathe whatsoever. Highly aerobic, active use would leave the wearer soaked with sweat, undermining the benefits of keeping rain or snow on the outside.

Left: Vietnam war era poncho. Right: Example of a disposable rain poncho.

The 1970s brought us technologies that revolutionized rain gear and transformed the outdoor clothing market. W.L. Gore & Associates patented an expanded polytetrafluoroethylene membrane with pores that allow vapor to escape, yet are so tiny that water drops cannot penetrate them. Hikers, anglers, and mountaineers rejoiced. For the first time, waterproof protection and breathability existed in the same garment, and by the mid-1980s, the outdoor clothing industry was in the midst of a paradigm shift.

An extreme skier climbs up a serac on Mount Berry, Antarctica in the late 1980’s. Photo by: Gordon Wiltsie

VAPOR-PERMEABLE MEMBRANES

Gore’s main patent for ePTFE (PTFE is the fluoroplastic widely used under the brand name Teflon®) expired in 1997. Now many similar membranes are used for rain gear, and more are continually being developed. Some of these membranes are made with polyurethane or silicone elastomers, and some with matted nanofibers. Their functionality is similar, though their construction and performance characteristics vary. The basic premise for all waterproof breathable membranes is the same—prevent water entry from the outside while allowing vapors (sweat) to escape from the inside. Let’s take a look at some of the different types of construction of waterproof/breathable fabrics.

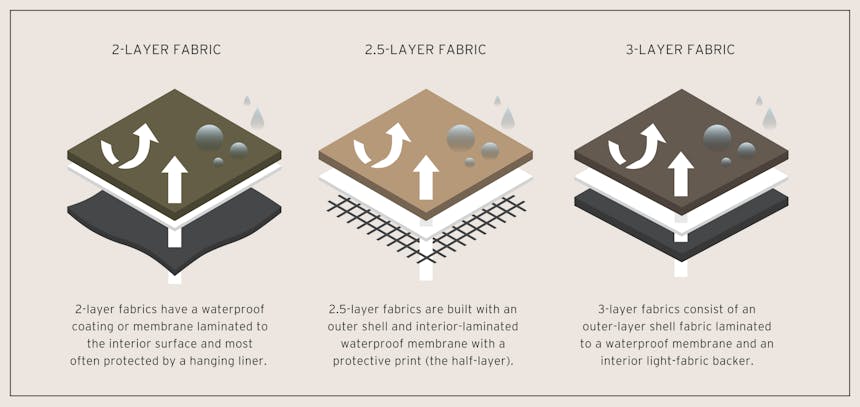

Three-layer laminated fabrics consist of a shell fabric with a waterproof membrane bonded to the inside surface. To protect the membrane, thin, brushed fabric is then laminated on the inside, sandwiching the membrane between the two layers. An example of this technology is Filson’s 3-Layer Field Jacket, which uses an extremely tough outer shell to withstand punctures and abrasion from the thorny cover often encountered while hunting upland birds.

Another way to protect the waterproof membrane is with a liner that is not bonded to the inside of the fabric. The Filson Skagit Waterfowl Jacket is built this way, with a fleece liner that protects the membrane and adds significant insulation. This is considered a two-layer fabric with a hanging liner.

2.5-layer jackets have waterproof membranes bonded inside the shell fabric, which are protected from interior abrasion with a printed mesh grid pattern or a highly-breathable, ultra-thin laminate or coating. This construction is used to create very lightweight, packable rainwear such as the Filson Swiftwater Rain Jacket.

HOW THEY’RE TESTED

For standardized comparison, waterproof fabrics undergo a hydrostatic head test, which measures the water pressure at which the fabric begins to leak. Imagine standing a cylinder atop a piece of fabric and filling it until the water’s weight creates enough pressure to force it through the fabric. Rather than using such a tall tube, however, the lab will pressurize the water to simulate a given water-column height. So, for example, a hydrostatic head rating of 10K means the fabric can withstand the pressure of a water column 10,000 mm tall before leaking. 10K is the threshold at which the fabric is considered waterproof and will keep you dry for extended periods in driving rain.

The other side of the equation is breathability. It does little good to keep water out if you’re getting sweat-soaked from the inside. There are several different tests used to measure breathability—the basic idea is to measure the amount of water vapor that can pass through the fabric during a given time span, typically 24 hours.

When measuring breathability, there are infinite variables that make it difficult to obtain test results that correspond to real-world performance. As an example, for warm, sweaty vapors to escape from inside the jacket, membranes require a difference in heat and humidity levels from inside to outside. So, a jacket will breathe much better when skiing on a low-humidity, cold, and clear day than it will in high humidity, such as when hiking in the clouds and getting rained on. Another variable is the nature of the fabric—Polartec® Neoshell® allows a minute amount of wind to pass through and mix with the warm air next to your body. This enhances breathability, but since the air in the testing lab is still, lab tests don’t reflect the NeoShell fabric’s actual breathability performance.

With so many variables that cannot be replicated in a static laboratory environment, test numbers should be viewed as a starting point only in comparing breathability between jackets. Don’t get caught up in chasing specs that tell only a part of the story.

Image A: high humidity – lower breathability | Image B: low humidity – higher breathability

FINDING A BALANCE

For highly aerobic wet-weather use, the ability to evacuate vapors is every bit as important as hydrostatic head specifications. Generally, the higher the hydrostatic head rating, the more difficult it will be for real-world moist vapors to escape, and the rain gear that will keep you driest is often the one that strikes the best balance between prevention of water entry and allowing vapor to escape.

While specs and ratings can be helpful in comparing technical rain gear, equally important are design considerations that optimize it for the intended use. A backpacker may choose a superlight jacket that can be packed into a grapefruit-size stuff sack, but that jacket probably won’t be the most durable choice for serious bushwhacking. A warmly insulated waterproof jacket is wonderful for sitting in a duck blind or deer stand, but may be uncomfortably warm for climbing in the steep country where chukars and bighorn sheep live. The trick is to determine your highest priorities based on end use: breathability, packability, tear-resistance, etc.

SEAL THE DEAL

To ensure that rain gear is truly waterproof, it needs appropriate sealing throughout. Gear with the best construction is fully seam-sealed, with thin, flexible tape heat-glued to all seams to prevent water leakage. Closures are also important—well-designed gear will use water-resistant zippers, storm flaps, or a combination of both. Hoods should be designed with good adjustment systems, to ensure a snug fit for when rain and snow are blowing sideways.

GO FORTH AND LEAK NO MORE

Today, we have more clothing solutions to protect us from the weather than ever before. Just as any well-stocked toolbox will have a variety of wrenches and sockets for specific tasks, waterproof rain gear can be a specific tool for a certain application or general purpose, like the ubiquitous adjustable wrench. Whether purpose-built for fishing, hunting, mountaineering, or backpacking, or universal, do-most-things-well tools, the market is full of technical rain gear. Choose the design that best suits your application, and make sure it’s built with the quality of design, materials, and manufacturing to make it a worthwhile long-term investment. Because that half-price jacket that leaves you wet and miserable on a weeklong through-hike in the North Cascades is really no bargain at all. In fact, it can be downright dangerous.