Buck Knives is a historic American brand, widely regarded as one of the very best American-made knife companies, with a legacy that spans four generations. For over a century, they’ve been dedicated to crafting quality, handmade knives, and tools designed for a life lived outdoors. While they’re a global leader in the sports cutlery industry, the journey began humbly in 1902.

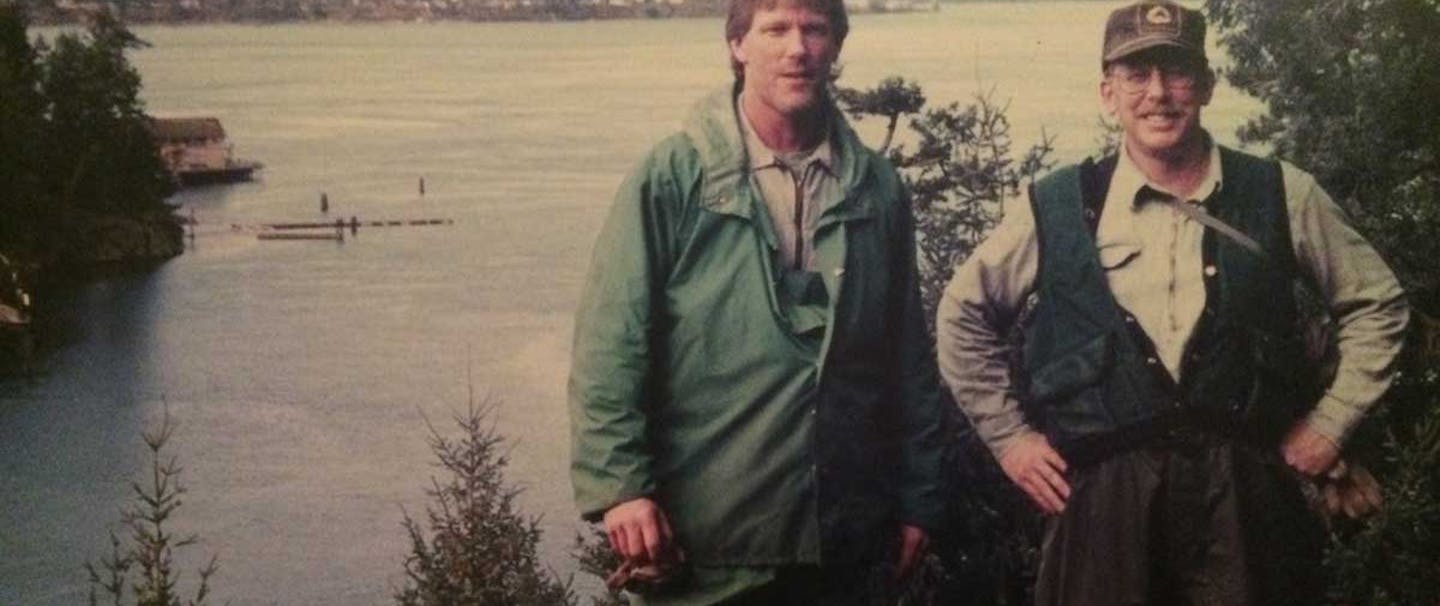

Hoyt Buck, a young blacksmith apprentice from Kansas, discovered a better way to temper steel that held an edge longer. In 1902, his initial experiments used grub hoes for raw material until he upgraded to worn-out files and rasps. After Hoyt retired in the early 1940s from working as a millwright on the Anderson Dam Project—a large reservoir outside his home in Mountain Home, Idaho—he seized an opportunity at a nearby Air Force base. “When Hoyt retired, he began pastoring at a small church, and in the basement of that church he was making knives for the local servicemen,” CJ Buck, the current CEO, and grandson of Al Buck told Filson in a recent interview. “They brought him the materials and he would make them the knives, mostly small fixed-blades, for free.”

Congress Street Factory - After incorporation in 1961, Buck Knives, Inc moved into this 3200 sq ft Quonset hut on Congress St. in San Diego’s Old Town area. No longer H.H. Buck and Son, the incorporation marked the end of what Al Buck described as a “Ma and Pa Operation.”

Hoyt’s contributions to the war effort ultimately led to the design of the 119 Special that is still manufactured to this day. Buck Knives’ expertise in craftsmanship later resulted in the first major upgrade to the M9 bayonet.

In 1945, Hoyt and his wife, Daisy, left Mountain Home, Idaho, and traveled to San Diego, California, to live closer to their son Al and his family of four children. Hoyt’s health was failing, but he recruited Al to establish H.H. Buck & Son, a Ma-and-Pa operation along the side of their house. “My dad [Chuck] and uncle helped out around there and would make knives, sharpen saws, and tune and service lawnmowers,” CJ said, describing their early days in the trade.

H.H. Buck & Son incorporated on April 7, 1961, and the passion project of making 25 knives a week rapidly gained momentum. Initial designs for the world-famous 110 Folding Hunter went into production and hit the market in 1964.

“It took the market by storm because it was the first dependable production-made folding lock-back knife in our industry,” CJ said. “It’s the right size for everything. We had ranchers, soldiers, policemen, electricians, fishermen, hunters—there was nobody that couldn’t find a use for that knife and didn’t have that knife hanging on their belt.”

Today, Buck Knives manufactures its products in Post Falls, Idaho. This process defines the best of the “Made in the USA” label.

“There was a time when ‘Made in the USA’ meant you were going to get a much higher quality of the product,” CJ said. “I think what we have been seeing is the detrimental impact to the United States overall by losing a lot of that manufacturing. We have seen other countries that export to the United States benefit from having that manufacturing.”

The creation of wealth for a nation is the value of American-made products. “Manufacturing takes $5 worth of raw materials and turns it into a $50 product,” CJ said. “That’s like taking a bunch of desert out in Nevada and turning it into the Las Vegas Strip.”

Hoyt and Al put Buck Knives on the map, but Chuck took the brand worldwide. Chuck and his wife, Lori, operated the company from 1979–1999. During the 1980s, they expanded the availability of their products from small independent dealers to mass merchants, which was the next stage of evolution for the business. In 1999, CJ took the realm and continues to advance the ingenuity of Buck Knives.

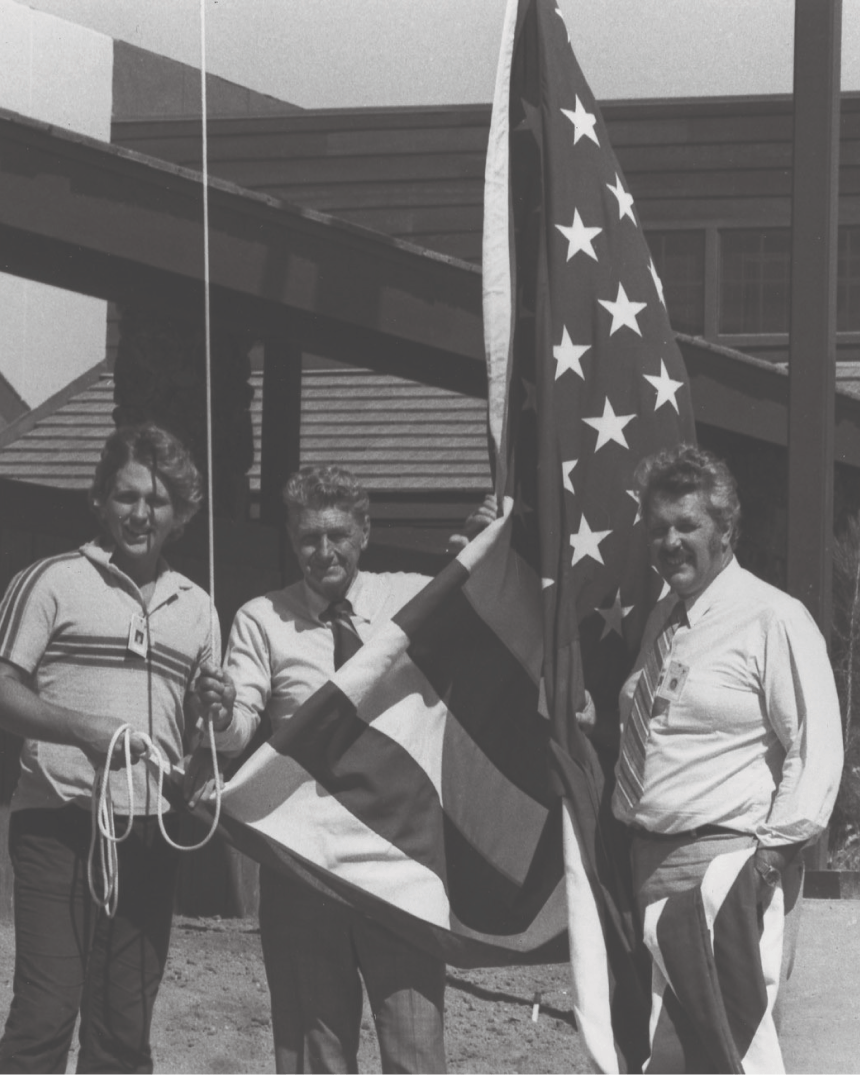

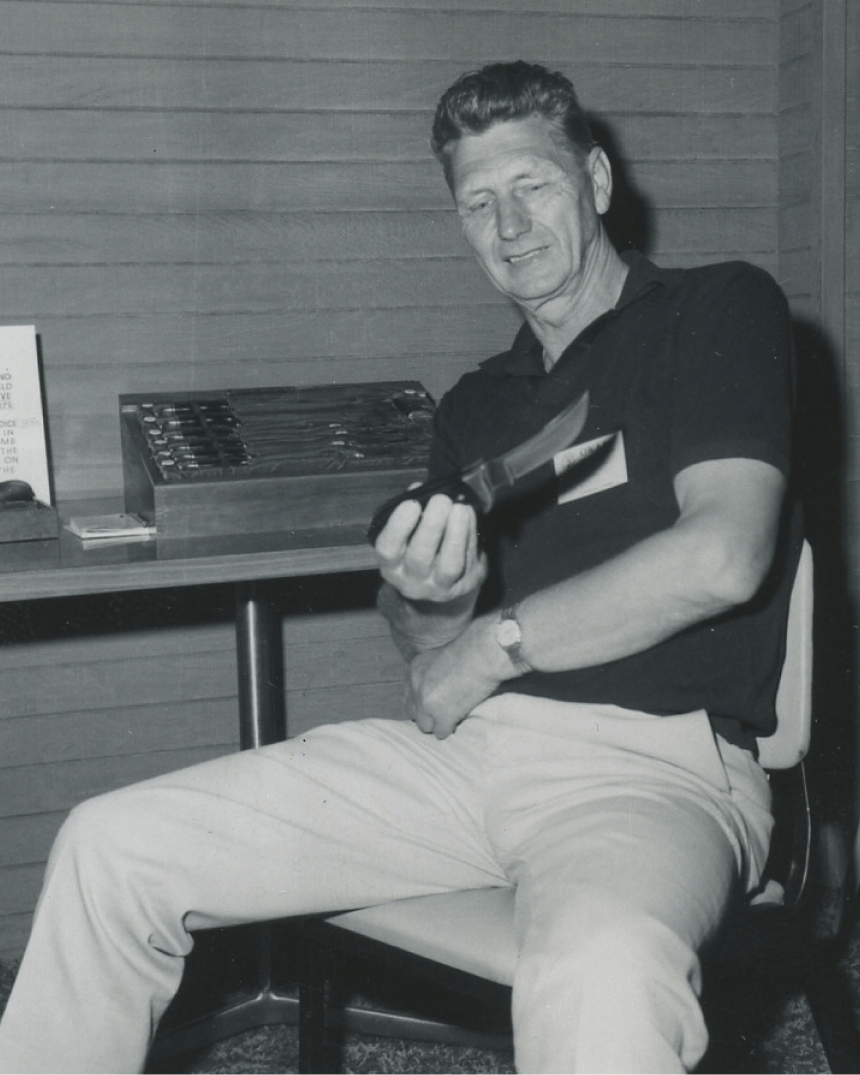

Image 1: CJ, Al, and Chuck Buck raise the flag at the opening of the Weld Facility in 1980. | Image 2: The legendary Buck Kalinga was a favorite of Al Buck’s, so much so he said, “We like to feel that the Buck Kalinga is also the badge of authority for all sportsmen to wear” circa 1969.

Buck Knives products are made

in Post Falls, Idaho. This process defines the best of the “Made in the USA” label.

One such advancement since 2019 is using Cerakote, a polymer-ceramic composite paint that is applied and baked. It puts a corrosion-free skin on top of the knife and enhances the balance between corrosion resistance, the ability to hold an edge, and the degree of softness. “One of the elements of being a good manufacturer is how many of the variable processes you control,” said CJ. “Bringing Cerakote in-house means we can control consistency and quality in the baking and the coating.”

Despite all their success, their modest roots keep them grounded. Every Buck Knives box comes with a Christian testimony, an idea from Chuck that provides a method of giving back to the community that’s supported them all these years.

_

In 2020, in addition to a modernized Buck® 110 Folding Hunter® Pro Knife, we premiered the Filson exclusive Buck® 106 Compadre Axe, and the Buck® 104 Compadre Camp Knife – featured for the first time in Hunter Orange from Cerakote with Tin Cloth Micarta handles.